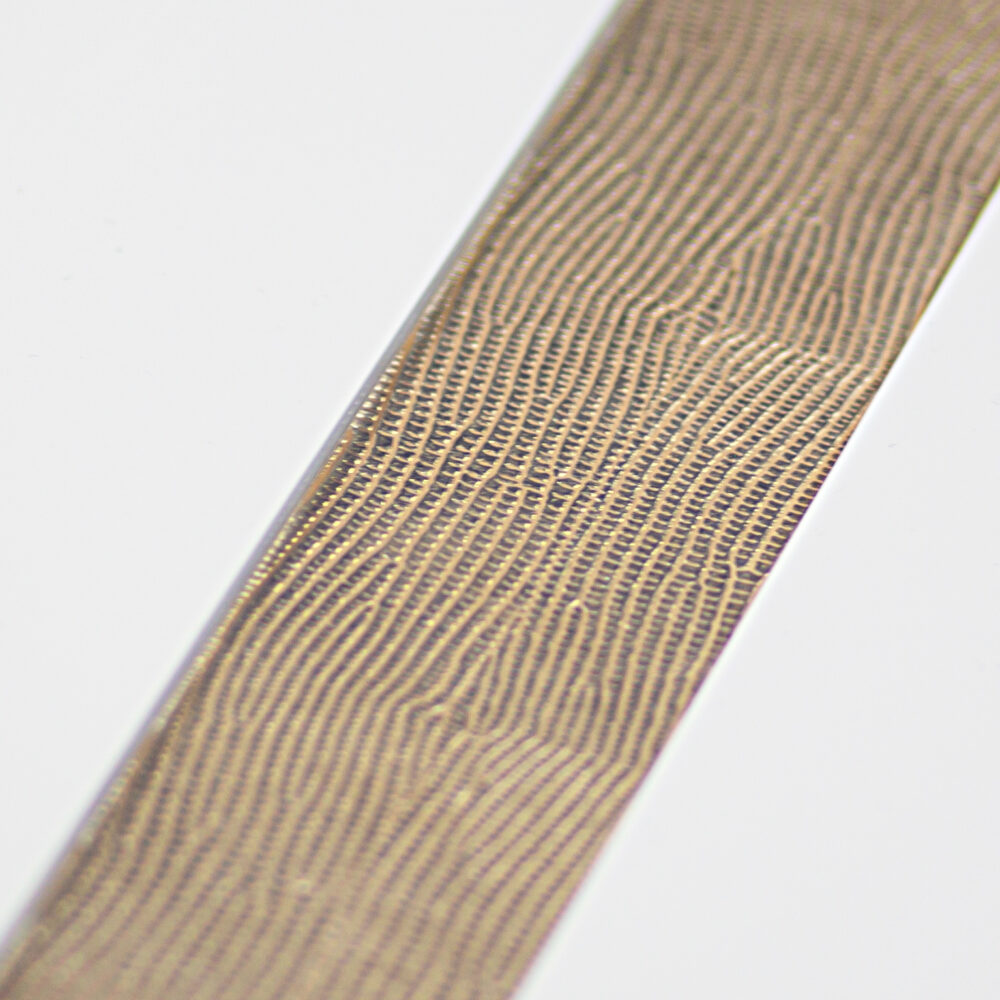

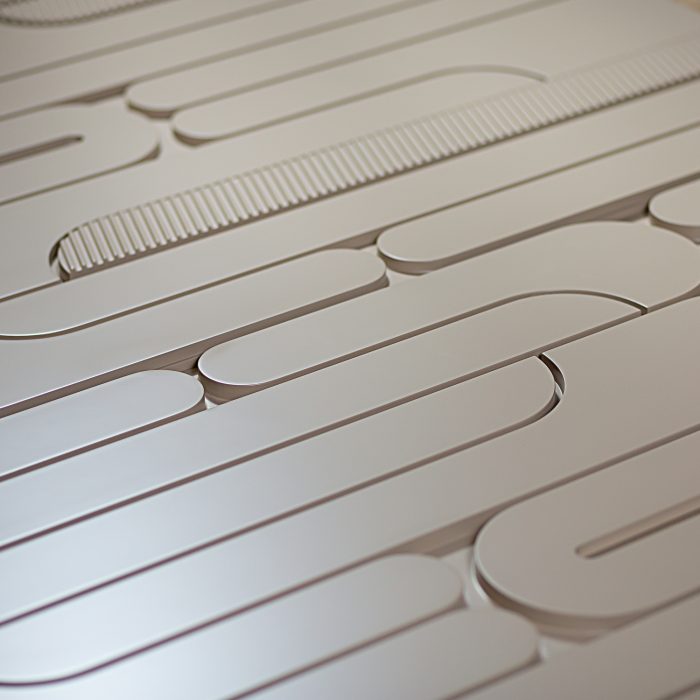

Satin surfaces and undulating shapes.

In the Praline Blush Pink version, the softly rounded lines strongly contrast with a black Lacobel float glass insert, the Praline White Porcelain version features a softly shimmering Sibuglas insert with crocodile skin pattern. Mini Praline Cappuccino panels attract attention with a mirror finish stainless steel insert.

Praline comes in three colours.

Blush Pink – subdued powder pink and White Porcelain – off-white, whereas Mini Praline with sized down pattern comes in Cappuccino.

PRALINE – White Porcelain – NCS S 1000-N

PRALINE – Blush Pink – NCS S 2005-R40B

mini PRALINE – Cappuccino – NCS S 4010 Y30R

Its soft shapes promote a relaxing spa-like ambience, it is perfect for bedrooms or interiors in which we wish to create a peaceful ambience.

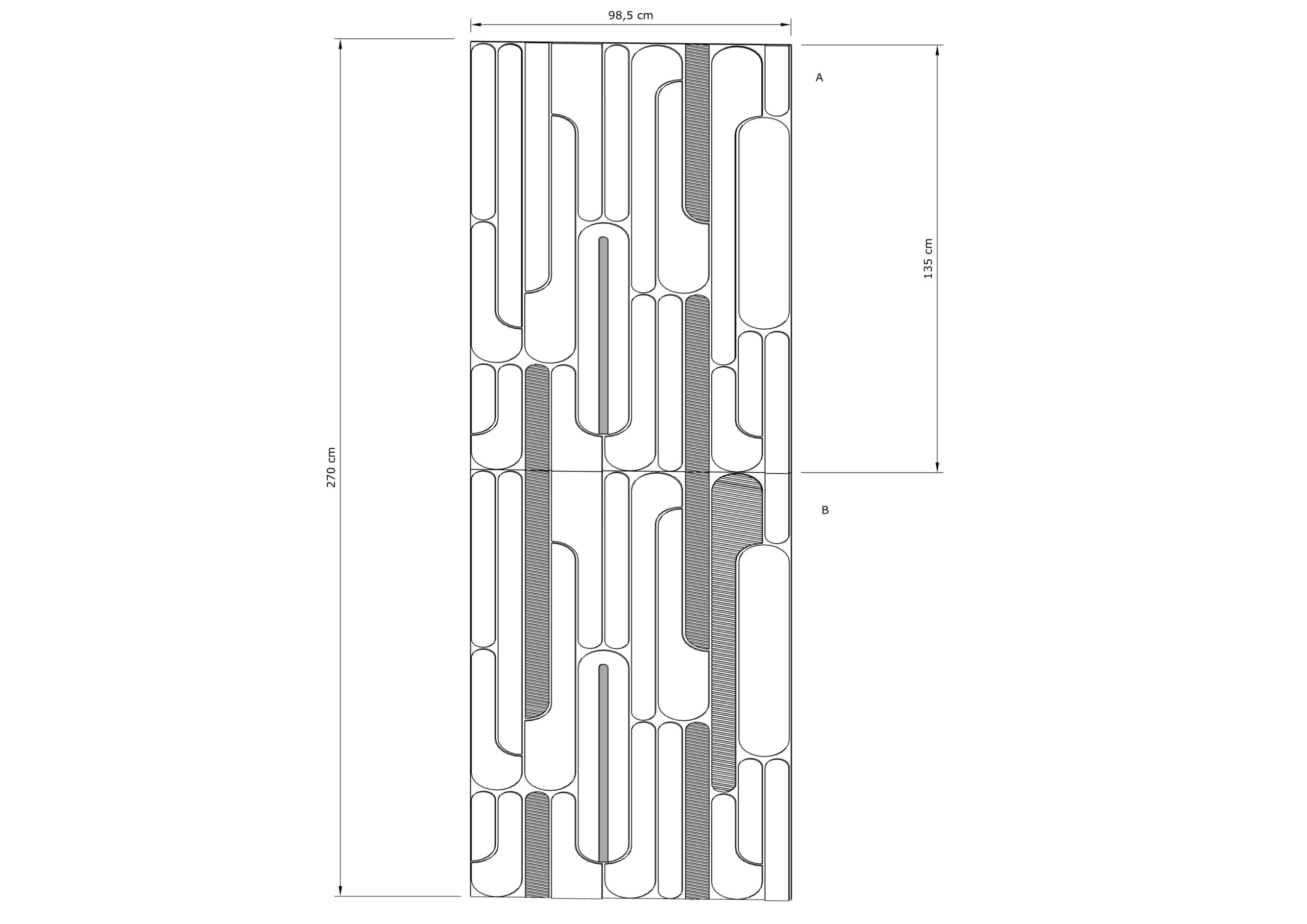

Praline

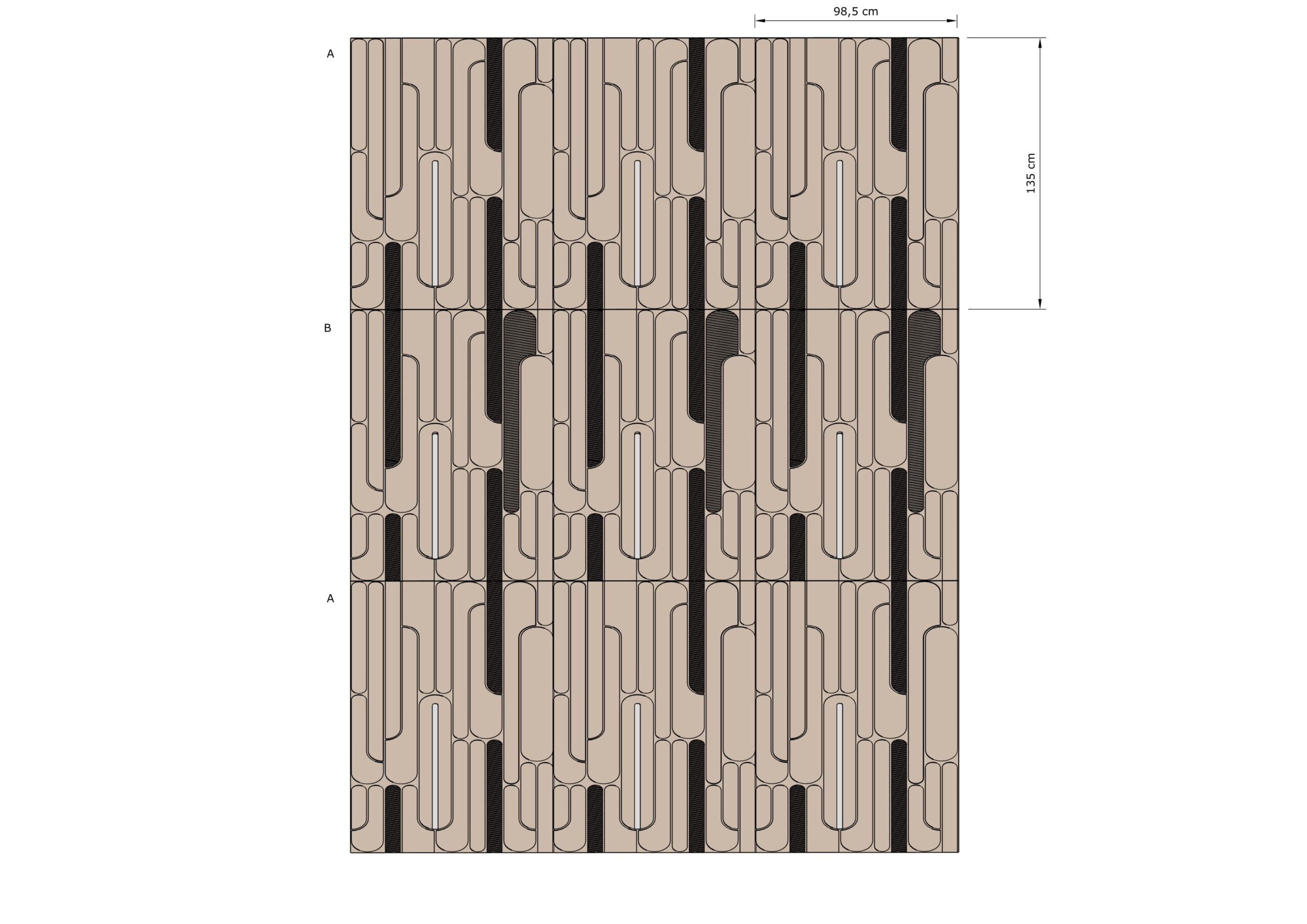

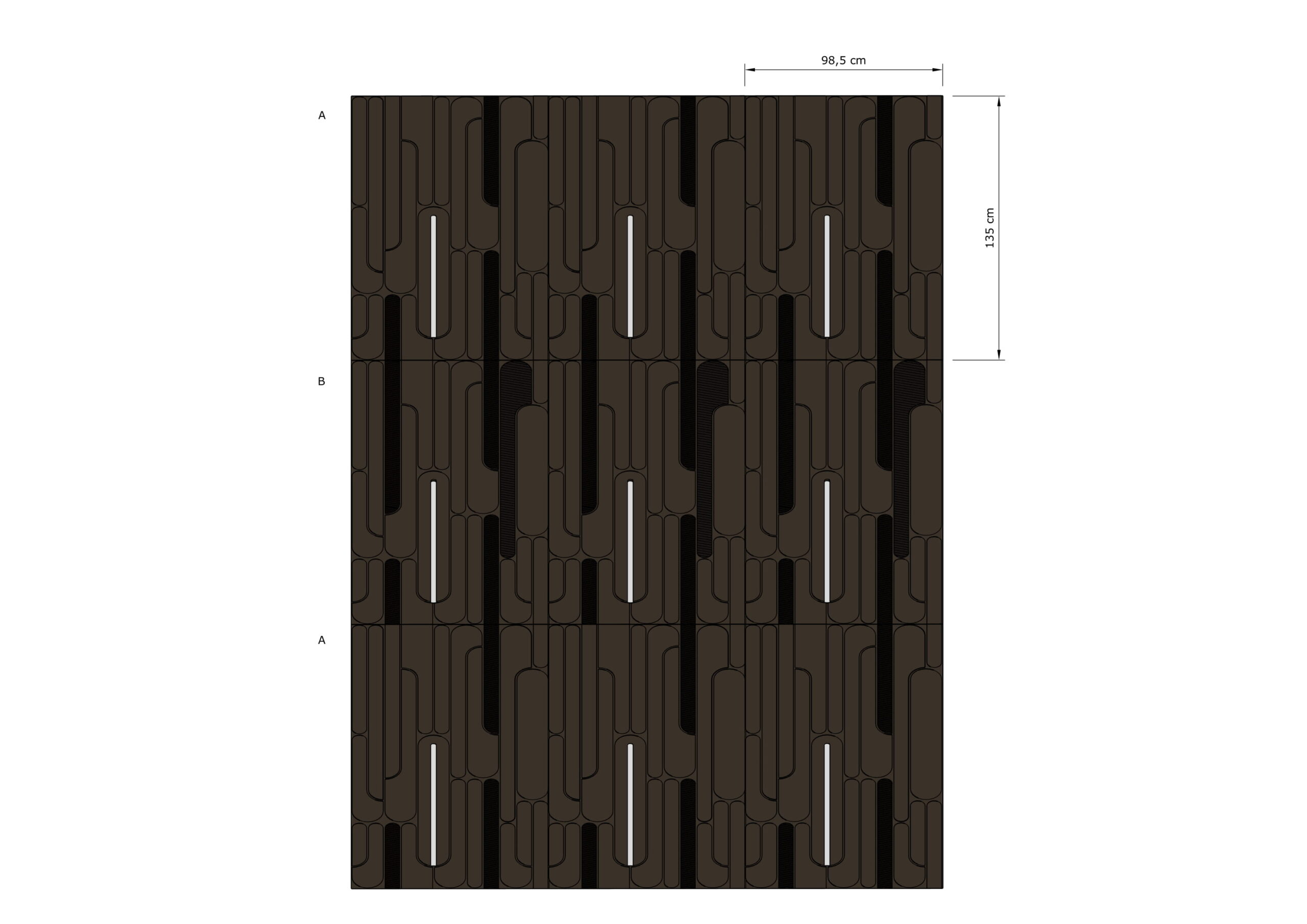

mini Praline

TECHNICAL DATA

Dimensions

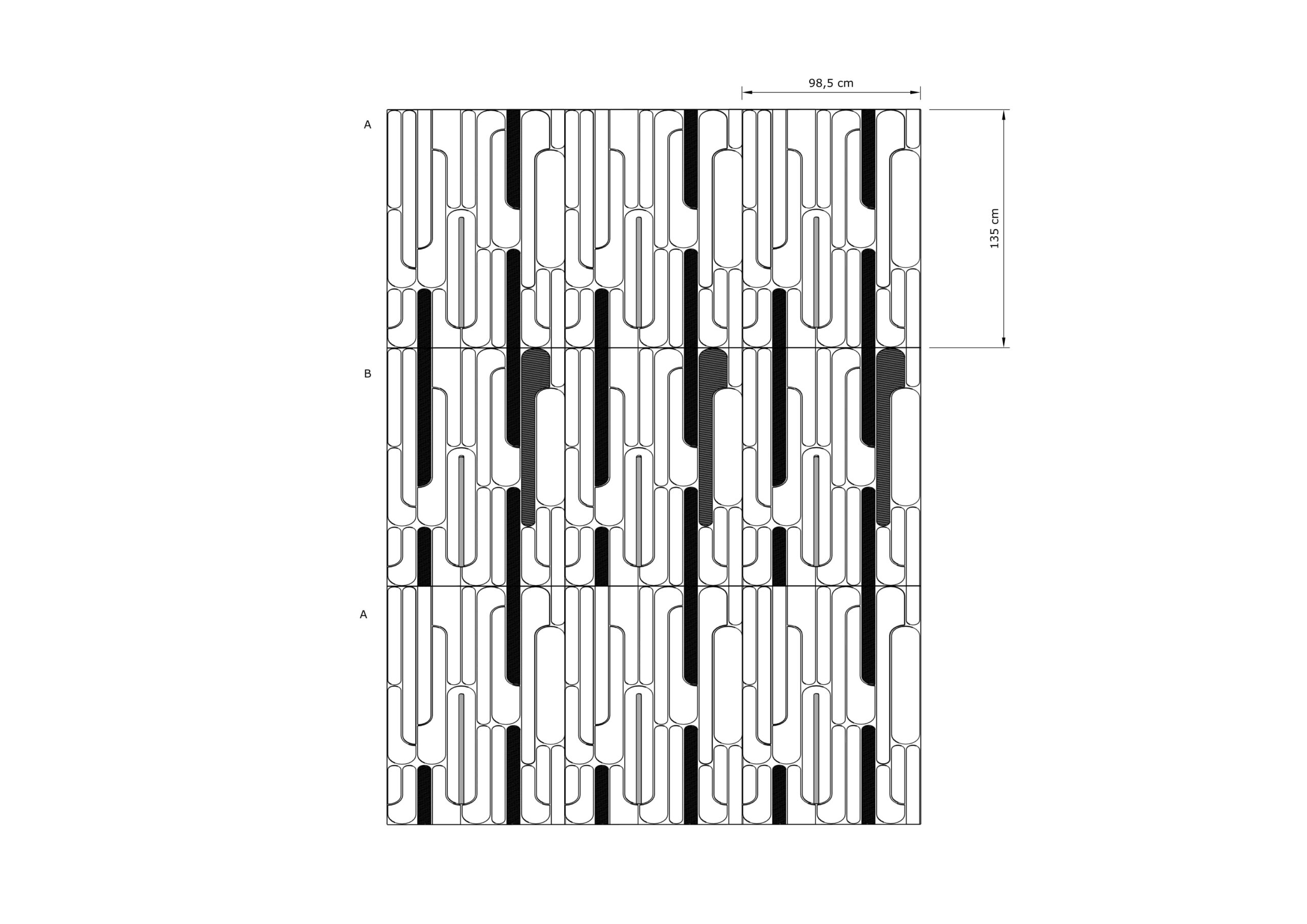

MINI PRALINE PANEL

Height: 1350 mm

Thickness: 27 mm

Weight:

Width: 985 mm

Area: 1,33 m²

Dimensional tolerance in accordance with EN 622-5:2009 standard ±1 mm depending on the batch.

PRALINE PANEL

Height: 922 mm

Thickness: 27 mm

Weight:

Width: 975 mm

Area: 0,90²

Dimensional tolerance in accordance with EN 622-5:2009 standard ±1 mm depending on the batch.

Material specification

Materials used - mini Praline

Valchromat board coloured through covered with satin varnish, solid wood board, mirror finish stainless steel.

Materials used - Praline

Valchromat board coloured through covered with satin varnish, solid wood board.

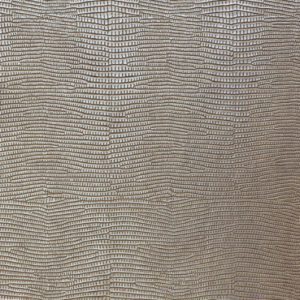

• Sibuglas - crocodile skin - White Porcelain version

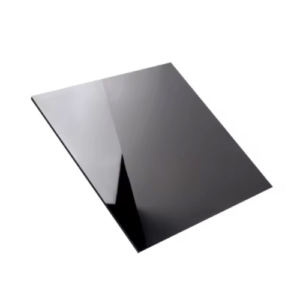

• Black Lacobel float glass - Blush Pink version

Product name

• Praline Blush Pink

• Praline White Porcelain

• mini Praline Cappuccino

Sturdiness

Balancing backside material prevents deformation, ensuring panel sturdiness.

Durability

30% harder and more resistant to mechanical damage than traditional panels.

Our panels are environmentally friendly

Owing to the use of natural materials and reduced quantity of harmful chemicals, they can be safely used within the reach of children.

Installation guide

1. Determining the fixing line

- Using a cross line laser or spirit level, determine the horizontal fixing line 300 mm above the floor level (maintaining a compensation gap of 20 mm).

- Place the batten against the laser line – the perpendicular edge and elongated mounting holes (“bean holes”) enable accurate fitting to the level.

2. Preparing the batten for fitting

- Cut the excess batten length to size, in order to fit it to the wall end.

3. Fixing the batten to the wall

- Place the batten against the wall and draw points for Ø7 mounting holes. Apply Ø6/80 mm wall plugs (from 4 to 6 pcs) in the marked points.

- Elongated mounting holes (“bean holes”) enable adjustment of the batten in relation to the fixing line.

- If the wall is uneven, the fixing points should correspond to the points in which the batten contacts the wall – do not bend the batten.

4. Securing and completing the installation

- The process should be repeated for subsequent panels, attention being paid to any possibly uneven walls that may require additional fitting adjustments.

Due to available adjustment options and accurate fitting of the batten to the wall, installation is smooth and ensures the stability of the entire structure